Bleeding External Clutch Hydraulic Release Systems with Bleed Screws

How to Bleed Air from a Hydraulic System. Locate the bleed valve. This valve is used to release excess pressure and air from the system. Open the bleed valve. Open the bleed valve by turning it counterclockwise until it is fully open. Allow the air to escape. You may notice bubbles in the fluid as the air escapes from the system.

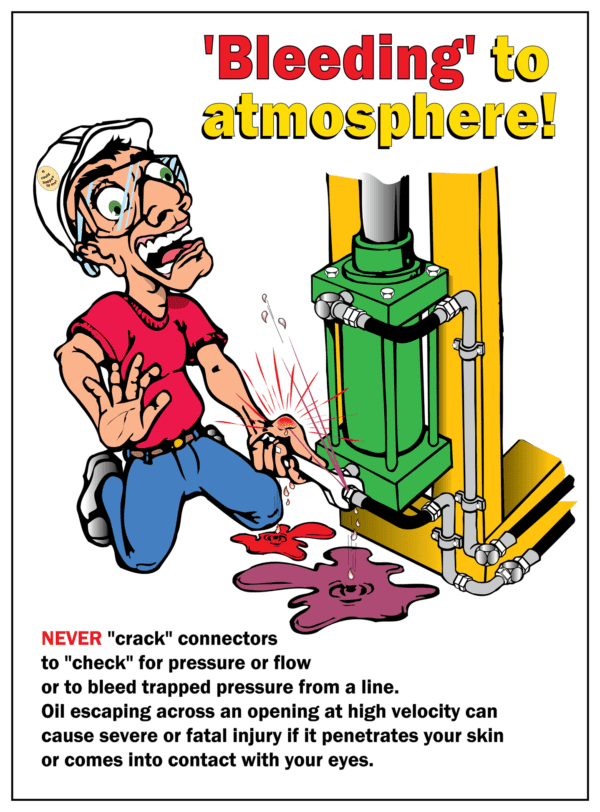

Bleeding to Atmosphere! Hydraulic Safety Posters

How To Bleed Air From A Hydraulic System. One of our members writes: "We have a simple hydraulic system: pump and 4 double-acting cylinders. Most of the oil between the directional control valve and cylinders 'shuttles' back and forth in the lines without returning to tank. The manufacturer of the system, Rexroth, tells me there is never.

Hydraulic Slave Cylinder Bleeding Procedure (How To) YouTube

Defining bleeding a log splitter can be simply put as a process to remove any air pockets trapped in the hydraulics. The presence of air in the hydraulic system results in the loss of power in the ram of the log splitter. As the hydraulic fluid is displaced by the air, the pressure that was applied to the ram also reduces.

BLEEDING AIR from the cooling system with the “spill free funnel

Step 3: Bleed the Air Out. Once the bleeder screw is prepared, you can begin to bleed the air out of the hydraulic cylinder. This involves slowly turning the bleeder screw counter-clockwise until you hear a hissing sound. As the air is released, you should see a steady stream of fluid coming from the bleeder screw.

Bleeding Air From Hydraulic System farewellmoms

1. Locate the Bleed Valve. Before you begin the bleeding process, you must first locate the bleed valve on your hydraulic cylinder. The bleed valve is typically a small valve or screw, often found at the topmost part of the cylinder or near the hose connections, depending on the design of the cylinder.

Video Why Bleeding a Hydraulic Clutch is Important OnAllCylinders

Allow the air to rise to the top: If you're bleeding a cylinder, extend it fully and let it sit for a few minutes so the air rises to the top. Release the air: If you're bleeding a cylinder, partially close it, but open the bleed valve on top. When the valve starts leaking hydraulic fluid, the air has been bled from the cylinder.

How to Bleed Air from a Hydraulic Cylinder Enerpac Blog

The process of bleeding air from a hydraulic brake system is simple, but it can become absolutely infuriating in no time for seemingly no reason. Luckily, Davin is here to help you stay out of trouble with the latest Hagerty DIY. Removing the air from a hydraulic brake system is critical to proper function.

How to Properly Bleed Air from a Dump Truck Cylinder Hydraulic

Once you have most of it out, open the screw fairly wide and get a helper to push down heavily on the clutch pedal the quickly close the screw. Repeat one or two times if necessary. The force of the clutch pedal being firmly depressed is enough to drive all the air out. 2013-09-23 15:24:07 # 12000. Comment by Brian M.

How To Bleed BVA Hydraulics YouTube

It's important to note that the process of bleeding air from a hydraulic system can vary depending on the specific type of equipment or system you are workin.

Bleeding Air from the Hydraulic Side of a Diaphragm Metering Pump YouTube

Tighten the bleeder screw or fitting securely. Bleeding method 2: Utilizing a vacuum pump for efficient air removal. Connect a vacuum pump to the bleed point using the appropriate adapter or hose. Operate the vacuum pump to create a negative pressure, drawing out the air from the hydraulic system.

Bleeding Air From Hydraulic System farewellmoms

Dec 10, 2012 / How to remove air in hydraulic system. #2. I have solved my problem. Under the machine and on the hydraulic pumps, there are bypass valves which can be used to disengage the hydraulics for moving the machine without engine power. On my older mower, there are two round knobs ( in front of motor about the height of the motor.

Air/Hydraulic Bottle Jack Bleeding Video YouTube

Here's how to get the air out of the hydraulic cylinder: Move the air to the top of the cylinder for effective release. Extend the cylinder fully and leave it in this position to allow the air to rise. Partially close the cylinder when all the air has risen to the top of the cylinder. Open the bleed valve for the air to escape.

How To Bleed Marine Hydraulic Steering EASILY. YouTube

Attach your hose to the cylinder - if empty of oil it will take longer to bleed. If your cylinder is double acting, attach hoses to both couplers and use a double-acting pump. Next, place the hydraulic cylinder below the pump - either by elevating the pump or lowering the cylinder. Try to position the cylinder with the ports facing up.

Bleeding the Hydraulic System HydroELectric

Remember to work only on a level surface. To make bleeding the air a lot easier, the surface needs to be level. 3. Remove the components and parts in your way. If possible, you should remove any components or parts from the system to easily access the lines being bled easier. 4. First, bleed the farthest lines.

Bleeding Air From Hydraulic System farewellmoms

Steps For Bleeding a Log Splitter: I cannot stress enough the importance of bleeding the hydraulic lines. If there's air in the system, your ram is never going to reach full power. Many models will self bleed merely by moving the wedge back and forth a dozen cycles or so. But you can also follow these steps to bleed the air out: Step 1:

Bleeding Air From Hydraulic System farewellmoms

Connected to the hydraulic system, the clean pressurized fluid pumps through the cylinder or reservoir, forcing out the air, debris, and old fluid through the bleeder tube. Users often bleed as part of a standard maintenance process for hydraulic cylinders. Usually, it is after disassembling components that may get in the way.